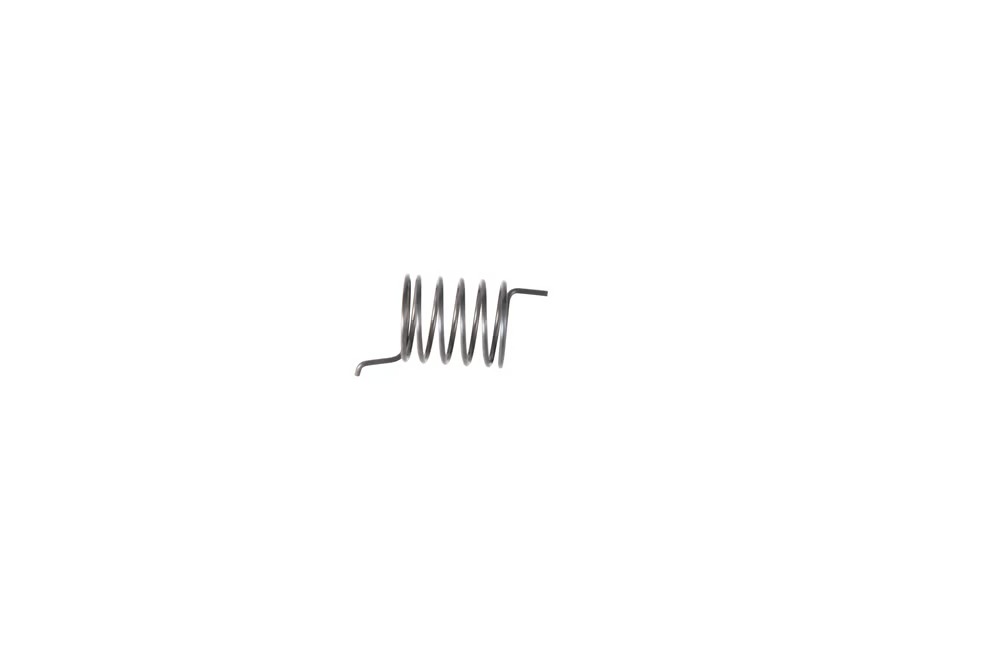

Understanding Torsion Springs: A Brief Introduction

Torsion springs are a type of mechanical spring that store and release rotational energy when twisted or torque is applied to them. These springs are widely used in various industries and applications due to their unique characteristics and efficient performance. In this article, we will explore the concept of ideal torsion springs, their features, applications, and benefits.

The Characteristics of Ideal Torsion Springs

Ideal torsion springs possess specific characteristics that make them suitable for various applications. These characteristics include:

- High torque output

- Accurate rotational energy storage

- Resistance to fatigue and wear

- Ability to withstand high temperatures

- Excellent dimensional stability

Applications of Ideal Torsion Springs

Ideal torsion springs find applications in a wide range of industries and devices. Some common applications include:

- Automotive suspension systems

- Garage doors and security gates

- Medical devices and equipment

- Aerospace and aviation components

- Industrial machinery and equipment

The Advantages of Using Ideal Torsion Springs

Ideal torsion springs offer several advantages over other types of springs. These advantages include:

- High energy storage capacity

- Compact design and space-saving

- Reliable and long-lasting performance

- Customizable to specific requirements

- Cost-effective solution

Factors to Consider When Choosing Ideal Torsion Springs

When selecting ideal torsion springs for your application, there are several factors to consider:

- Load requirements: Determine the amount of torque and rotational energy the spring needs to handle.

- Material selection: Choose the appropriate material based on factors such as temperature, corrosion resistance, and durability.

- Wire size and shape: Determine the optimal wire diameter and shape for the desired torque output.

- End configurations: Consider the required end configurations, such as straight ends, hooks, or loops, to ensure proper installation and functionality.

- Space constraints: Take into account the available space for the spring to ensure a proper fit within the application.

Maintaining Ideal Torsion Springs: Best Practices

To ensure optimal performance and longevity of ideal torsion springs, it is essential to follow these maintenance practices:

- Regular inspection: Check for signs of wear, fatigue, or deformation.

- Lubrication: Apply appropriate lubricants to minimize friction and prevent corrosion.

- Proper storage: Store springs in a clean and dry environment to avoid contamination and damage.

- Replacement: Replace worn-out or damaged springs promptly to prevent failure and potential safety hazards.

Common Issues and Troubleshooting

Despite their reliability, ideal torsion springs may encounter certain issues. Here are some common problems and troubleshooting tips:

- Loss of torque: Verify that the spring is correctly installed and free from any obstructions or binding.

- Noise and vibration: Check for misalignment or inadequate lubrication, and address any issues accordingly.

- Corrosion: Regularly inspect and apply anti-corrosion coatings to protect the spring from environmental factors.

- Breakage: Ensure the spring is not subjected to excessive load or over-torquing, as this can lead to breakage.

Conclusion

Ideal torsion springs offer a reliable and efficient solution for various applications that require rotational energy storage. By understanding their characteristics, applications, and maintenance practices, you can make informed decisions when selecting and utilizing these springs. Remember to consider factors such as load requirements, material selection, and maintenance to maximize the performance and longevity of ideal torsion springs.