Introduction: Understanding constant tension springs

Constant tension springs are a crucial component in various mechanical devices and systems. These springs are designed to exert a consistent amount of force throughout their compression and extension cycles, making them ideal for applications that require a reliable and uniform force. In this article, we will delve into the world of constant tension springs and explore their construction, uses, benefits, and more.

1. The Basics of Constant Tension Springs

Constant tension springs, also known as constant force springs, are a type of extension spring. Unlike traditional extension springs, which exert a force that increases as they extend, constant tension springs provide a consistent force throughout their entire range of motion. This is achieved through the use of tightly wound coils that are formed in a specific manner to ensure a steady force output.

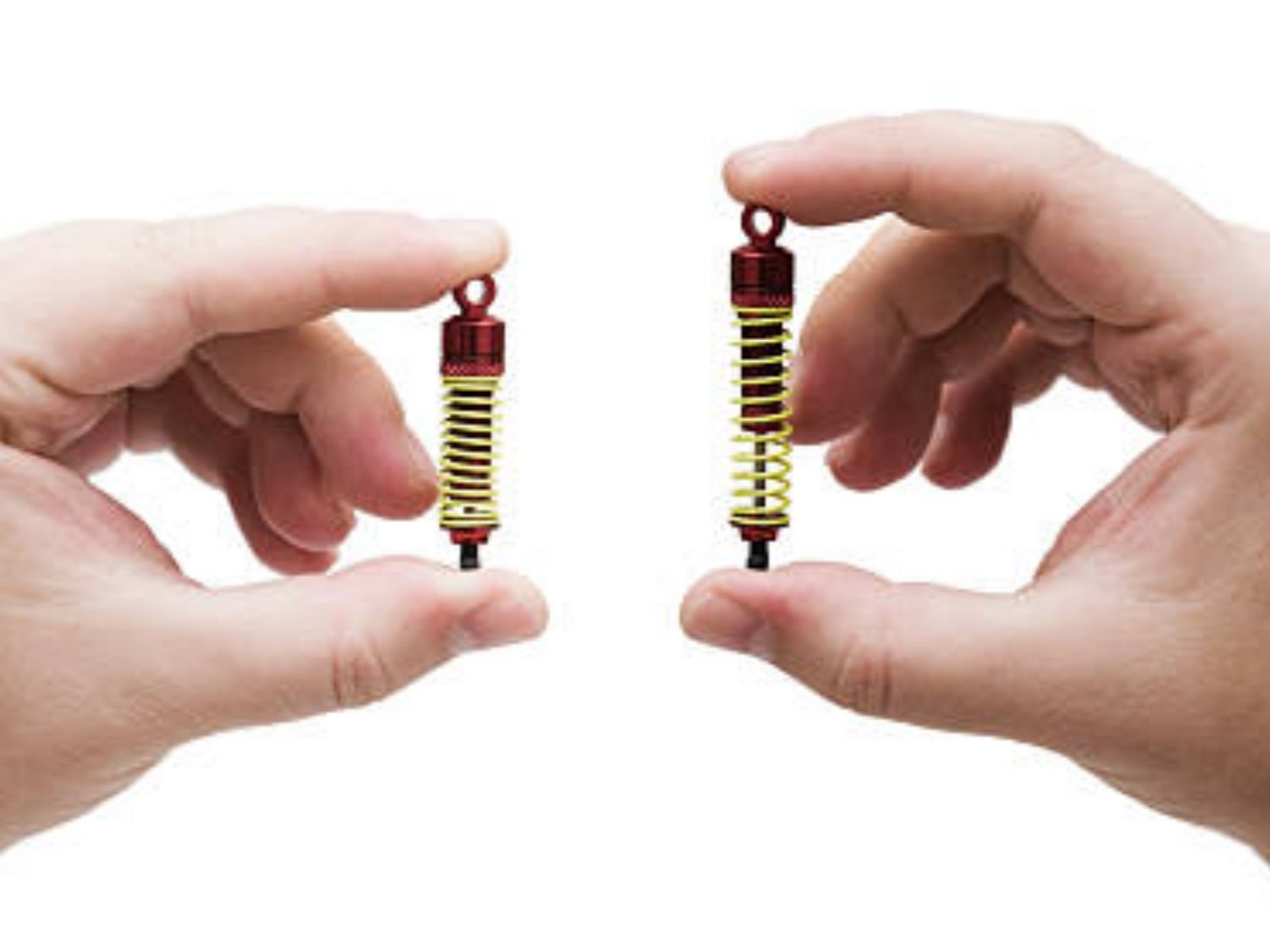

2. Construction and Design of Constant Tension Springs

Constant tension springs are typically manufactured from high-quality materials such as stainless steel or carbon steel. The tightly wound coils are precision-engineered to ensure consistent force output, and the ends of the spring are often attached to different components or surfaces to create tension. The design of constant tension springs allows them to exert a force that remains constant regardless of the extension or compression distance.

3. Applications in Automotive Industry

The automotive industry extensively relies on constant tension springs for various applications. One common use is in seat belt retractors, where constant tension springs ensure that the seat belt is always taut, providing maximum safety to the occupants. Constant tension springs are also utilized in throttle return mechanisms, ensuring smooth operation and reliable performance.

4. Importance in Medical Devices of Constant Tension Springs

In the medical field, constant tension springs find numerous applications. They are widely used in devices such as retractors, clamps, and surgical instruments that require a consistent and reliable force. Constant tension springs play a crucial role in maintaining tension during surgeries, enhancing precision, and reducing the risk of complications.

5. Role in Electronics and Electrical Equipment

Constant tension springs have proven invaluable in the electronics and electrical industry. They are commonly found in retractable cords, ensuring the cables remain taut and organized when not in use. These springs also find applications in connectors and switches, providing reliable contact force and improving overall performance.

6. Benefits of Constant Tension Springs

Constant tension springs offer several advantages over traditional extension springs. Firstly, their consistent force output ensures a predictable response in various applications. This reliability minimizes the risk of malfunction and enhances overall system performance. Additionally, constant tension springs are known for their longevity and durability, making them a cost-effective choice in the long run.

7. Considerations for Design and Installation of Constant Tension Springs

When incorporating constant tension springs into a design, it is crucial to consider factors such as load requirements, available space, and environmental conditions. Proper installation, including correct positioning and attachment, is essential for optimal performance. Consulting with a spring manufacturer or engineer can help ensure that the chosen constant tension spring is suitable for the specific application.

8. Maintenance and Care

To maintain the functionality of constant tension springs, regular inspection and maintenance are necessary. This includes checking for signs of wear, corrosion, or fatigue that may affect their performance. Lubrication, when appropriate, can help reduce friction and extend the lifespan of the springs. Following the manufacturer's guidelines for maintenance is crucial to maximize the performance and longevity of constant tension springs.

9. Exploring Customization Options

Constant tension springs can be customized to meet specific requirements and applications. This customization may involve adjusting the force output, altering the dimensions, or modifying the end attachments. Working closely with a spring manufacturer or engineer can help ensure that the constant tension spring is tailored to the unique needs of the project, optimizing its performance.

10. Future Trends and Innovations

The field of constant tension springs continues to evolve, driven by advancing technologies and emerging needs. Ongoing research and development aim to improve the materials used, enhance the design and manufacturing processes, and explore new applications. As industries continue to demand reliable and precise force solutions, constant tension springs are expected to play a vital role in the future.