The Mechanics and Applications of Torsion Springs

A torsion spring is a mechanical device that stores and releases rotational energy. It is a type of spring that works by twisting or rotating around an axis, exerting a torque in the process. Torsion springs are widely used in various applications, from industrial machinery to everyday objects. In this article, we will explore the mechanics and applications of torsion springs in detail.

1. Understanding Torsion Springs: How They Work

Torsion springs are helical springs that exert a torque or rotational force. They are typically made from round wire and have a body or coil that is tightly wound. When a torsion spring is twisted around its axis, it stores mechanical energy. This energy can be released when the spring is untwisted or allowed to return to its original position. The amount of torque exerted by a torsion spring depends on its dimensions, material properties, and the angle of twist.

2. Design and Construction of Torsion Springs

Torsion springs are designed to withstand rotational forces and provide a predetermined amount of torque. The design and construction of torsion springs involve several factors, including wire diameter, coil diameter, body length, and number of coils. The material used for torsion springs is typically high-carbon steel, stainless steel, or various alloys. The choice of material depends on the specific requirements of the application, such as corrosion resistance or high-temperature resistance.

3. Applications of Torsion Springs

Torsion springs find wide-ranging applications in various industries and everyday objects. Some common applications include:

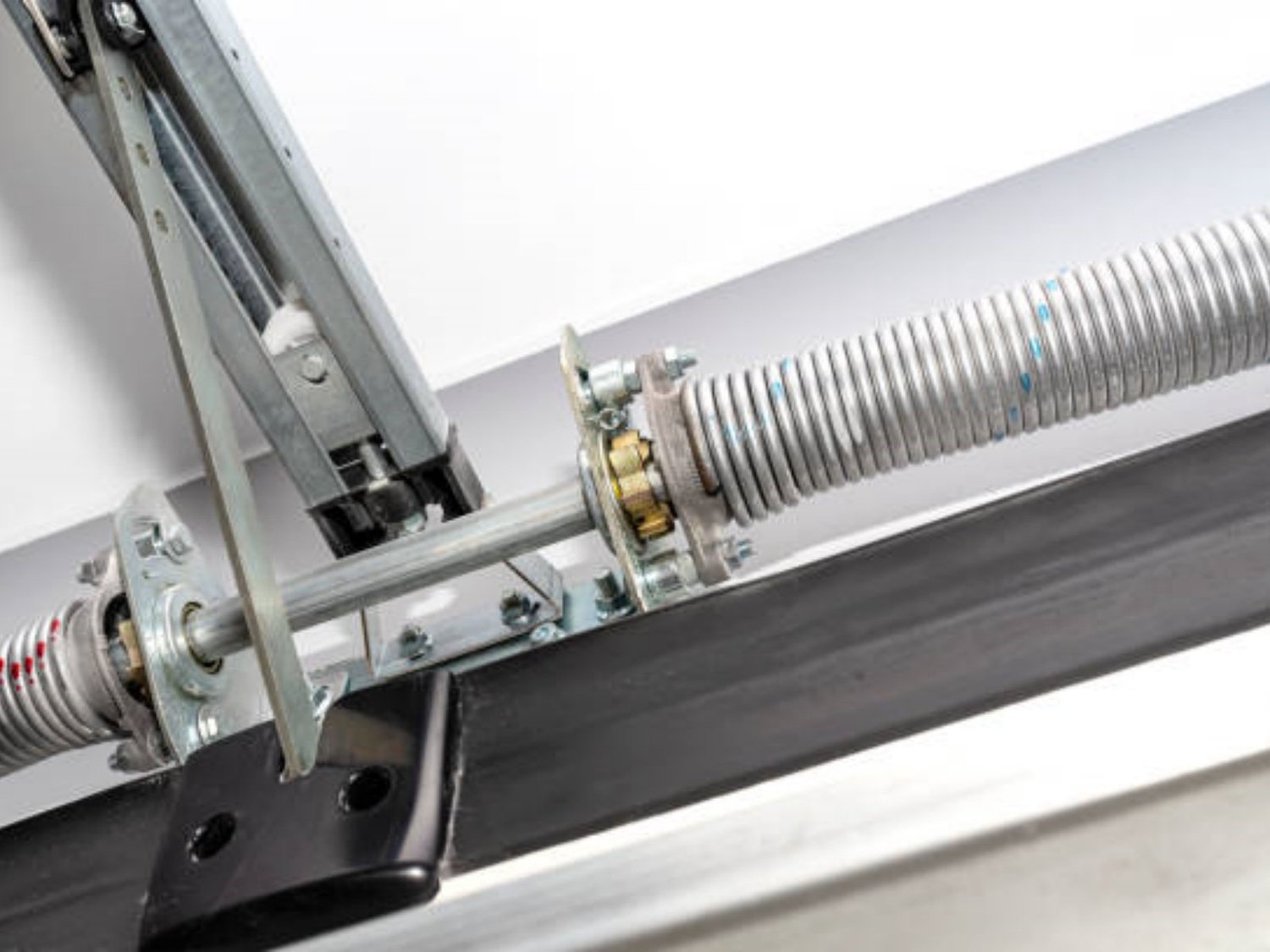

- Garage Doors: Torsion springs are commonly used in garage doors to counterbalance the weight of the door panels, allowing for smooth and controlled opening and closing.

- Clothespins: The familiar wooden or plastic clothespins utilize torsion springs to provide the necessary clamping force to hold clothes on a line.

- Clipboards: Torsion springs are used in clipboards to hold papers securely in place.

- Industrial Machinery: Torsion springs are widely used in various industrial machinery, such as automotive suspensions, agricultural equipment, and door hinges.

- Medical Devices: Torsion springs play a crucial role in medical devices like surgical instruments, ensuring precise and controlled movement.

4. Advantages of Torsion Springs

Torsion springs offer several advantages over other types of springs:

- Compact Design: Torsion springs can store a significant amount of energy in a compact space, making them ideal for applications with limited space.

- High Durability: Torsion springs are designed to withstand repeated cycles of twisting and untwisting without losing their performance.

- Wide Range of Load Capacities: Torsion springs can be designed to provide a wide range of torque capacities, allowing for customization based on specific application requirements.

- Predictable and Consistent Performance: Torsion springs offer predictable and consistent performance, making them reliable for critical applications.

5. Factors to Consider in Torsion Spring Design

When designing torsion springs, several factors need to be considered:

- Operating Environment: The operating environment, including temperature, humidity, and exposure to corrosive elements, influences the choice of material and surface treatment for the torsion spring.

- Deflection and Torque Requirements: The required torque and deflection determine the dimensions and properties of the torsion spring, including wire diameter, coil diameter, and body length.

- End Configurations: The end configurations of a torsion spring, such as straight or bent ends, affect its performance and installation method.

- Life Cycle Expectancy: The expected number of cycles and the desired lifespan of the torsion spring impact the choice of material and design considerations.

6. Maintenance and Safety Considerations

To ensure optimal performance and safety, torsion springs require regular maintenance and inspections. Here are some important considerations:

- Lubrication: Proper lubrication of torsion springs reduces friction and wear, extending their lifespan.

- Regular Inspections: Regular inspections help identify any signs of wear, fatigue, or damage that may compromise the functionality of the torsion springs.

- Safe Handling: When working with torsion springs, it is essential to follow proper safety procedures to prevent accidents and injuries.

7. Customization and Manufacturing of Torsion Springs

Torsion springs can be customized to meet specific application requirements. Manufacturers use advanced computer-aided design (CAD) software and precision manufacturing techniques to produce torsion springs with high accuracy and consistency. The manufacturing process involves wire forming, coiling, stress-relieving, and surface treatment, ensuring the final product meets the desired specifications.

8. Troubleshooting Common Issues with Torsion Springs

Occasionally, torsion springs may encounter issues that affect their performance. Here are some common problems and troubleshooting tips:

- Loss of Torque: If a torsion spring loses its torque, it may need to be replaced due to fatigue or wear. Consult a professional for proper replacement.

- Noise or Vibration: Excessive noise or vibration may indicate misalignment or lack of lubrication. Check for proper alignment and lubricate as needed.

- Inconsistent Performance: Inconsistent performance may be due to variations in the load or environmental factors. Consider adjusting the design or material selection.

9. Future Developments in Torsion Spring Technology

The field of torsion spring technology continues to evolve, driven by advancements in materials, manufacturing techniques, and design optimization. Future developments may include:

- Smart Torsion Springs: Integration of sensors and actuators to provide real-time feedback and adjust torsion spring performance as needed.

- Lightweight Materials: Exploration of lightweight materials with high strength and fatigue resistance for improved efficiency and performance.

- Customization and Rapid Prototyping: Advancements in manufacturing technologies may enable faster and more cost-effective customization of torsion springs.

10. Conclusion

Torsion springs are essential mechanical devices that store and release rotational energy. They find widespread use in various applications due to their compact design, durability, and predictable performance. Understanding the mechanics, design considerations, and applications of torsion springs is crucial for engineers, designers, and anyone working with mechanical systems.