The Basics of Tension Spring

Tension springs are one of the most used types of spring in various mechanical, automotive, industrial, and electronic tools and machines. The primary function of a tension spring is to provide a force opposing the tensioning force applied to the spring. Tension springs are typically made of elastic metal, such as stainless steel, and are designed to elongate by a certain amount when subjected to a load.

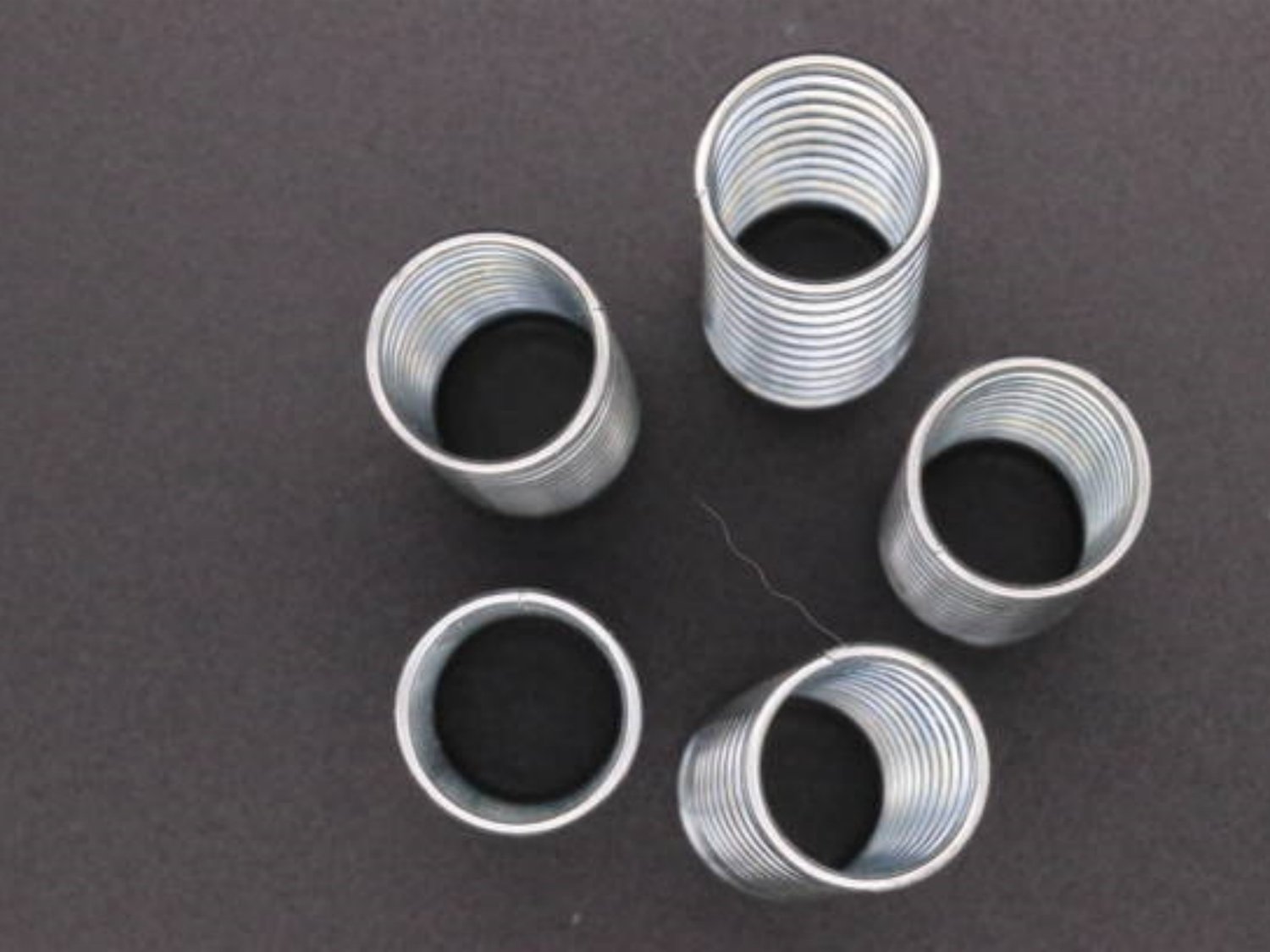

The Construction of Tension Springs

Tension springs are constructed using a variety of methods, depending on the intended use and the material used in the manufacturing process. These springs usually have a wound or coiled structure, with the end of the spring looped or bent to create a hook or a ring for attachment purposes.

The Purpose of Tension Springs

The primary purpose of tension springs is to resist tension force. These springs are also used in various applications such as garage doors, trampolines, and exercise equipment. Tension springs are also used in electrical switches and appliances to provide optimal contact pressure.

The Types of Tension Springs

There are various types of tension springs, each designed to meet the specific requirements of different applications. These include compression tension springs, extension tension springs, and torsion tension springs.

The Benefits of Tension Springs

Tension springs have numerous benefits such as providing consistent force over time, resistance to corrosion and rust, and long-term durability when compared to other spring types.

Tension Spring Maintenance

Tension springs should be frequently checked for wear and tear, rust, and corrosion. Any damaged or broken spring should be replaced immediately to ensure optimal performance.

The Manufacturing Process of Tension Springs

Tension springs are manufactured using specialized machines that allow for the precise coiling and shaping of the spring material into the desired shape and size.

The Design of Tension Springs

The design of tension springs can be customized to meet the specific requirements of various applications. These specifications include wire diameter, coil diameter, and material type.

Using Tension Springs

When using tension springs, it is essential to understand the load capacity and force required for the spring to perform optimally. Always ensure that the correct tension spring is selected based on the desired load and application requirements.

The Future of Tension Springs

With advancements in technology, there is a growing demand for stronger, more durable, and lightweight tension springs. As such, we can expect to see developments in the manufacturing and design of tension springs to meet these requirements. What is the tension spring, construction of tension springs, purpose of tension springs, types of tension springs, benefits of tension springs, tension spring maintenance, manufacturing process of tension springs, design of tension springs, using tension springs, future of tension springs What is the Tension Spring? A Comprehensive Guide Discover everything you need to know about tension springs in this comprehensive guide. Learn about the types, benefits, and maintenance of these essential springs.