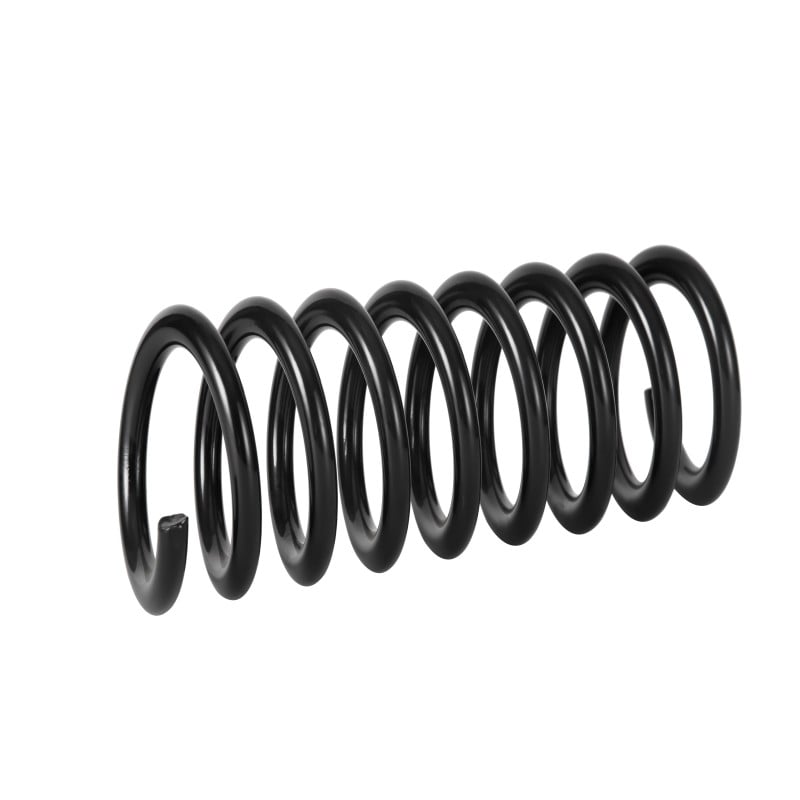

Progressive Suspension Fork Springs

Application:Specialized for customization according to customer requirements, with high rigidity.

Design team and technical team: Our design and technical experts collaborate to provide innovative and meticulously crafted products for clients. We specialize in spring design,manufacturing, and optimization.

One-stop service: Zhejiang Yurong Spring Co., Ltd. builds its own brand in terms of management mode, quality management, and brand image, earning trust and reliability.

Product Description

Progressive Suspension Fork Springs are high-performance springs designed to enhance the performance and comfort of your motorcycle's front suspension system. These springs are specifically engineered to provide a progressive rate of compression, meaning they become stiffer as they are compressed further. This unique design allows for a plush initial stroke, providing excellent small bump compliance, while still offering ample support for larger impacts.

The main function of Progressive Suspension Fork Springs is to improve the handling and ride quality of your motorcycle. By replacing the stock springs with these progressive springs, you can achieve a smoother and more controlled ride. These springs effectively reduce front-end dive during braking, improve cornering stability, and enhance overall suspension performance.

Product Application

Progressive Suspension Fork Springs are suitable for a wide range of motorcycles, including street bikes, sport bikes, and adventure bikes. They are compatible with various front fork types and can be installed on both stock and aftermarket suspension systems. Whether you are a casual rider or a professional racer, these springs can greatly improve the performance of your front suspension.

Product Quality Control

Progressive Suspension Fork Springs are manufactured using high-quality materials and undergo rigorous quality control procedures. Each spring is carefully inspected for dimensional accuracy, strength, and performance. The manufacturing process follows strict industry standards to ensure consistent and reliable performance.

Product Stability

The progressive design of these springs contributes to improved stability and control during various riding conditions. The gradual increase in stiffness provides a balanced and progressive feel, allowing the suspension to effectively absorb and dampen bumps and vibrations. This stability promotes better handling, increased confidence, and a smoother overall ride experience.

Product Safety

Progressive Suspension Fork Springs are designed and tested to meet the highest safety standards. They are engineered to withstand extreme conditions and provide reliable performance. However, it is important to follow the installation instructions provided by the manufacturer and regularly inspect the springs for any signs of wear or damage.